An online and offline Android app

bluebee® is a native Android app designed to take full advantage of the operating system’s capabilities, including full offline mode allowing usage when there is no signal, as is often the case in an industrial plant or in remote areas.

Robust off-the-shelf software

Unlike other mobile systems available in the market, bluebee® is a standard off-the-shelf product, which has been in the market since 2013. No custom programming is required, ensuring robustness and reliability.

Multiple choices of devices

bluebee® can be installed on normal Android phones or rugged industrial devices, including explosion-proof ATEX-certified models for use in hazardous environments. A Smart Glass plug-in is also available for hands-free usage.

Design & ergonomics

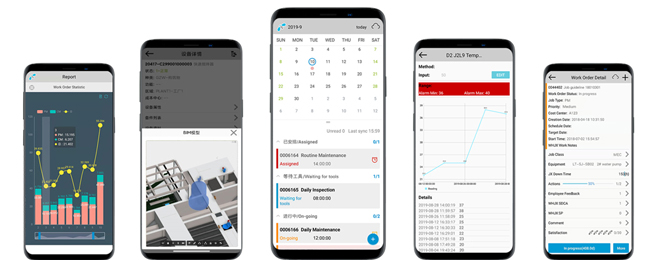

bluebee® is designed to assist technicians, not to downsize or control them. Manual input is replaced by scanning, taking photos, selecting values and automatic capture of time and location, ensuring perfect accuracy and ease-of-use.

A catalyst for best practices

bluebee® acts as a structuring tool to motivate workers, to train them on-the-job, to organize them around clear processes and to gently enforce best practices from top managers to workers.

Support for work execution

bluebee® supports all onsite activities: receiving work orders from any back-office system, reporting work done, inspection results, meter readings and measurements. bluebee® also allows users to visualize trends and graphical reports.

bluebee® scan

Anyone, even non-registered bluebee® users can report incidents, production, events, etc with their phone by quickly scanning the equipment QR code. The same concept or apply to simple repetitive tasks, such as cleaning routines, security rounds, assets inventory, patrols, HSE checkpoints, etc.

QR codes, RFID tags, NFC tags

Areas, equipment and inspection points can be identified by QR codes or RFID tags. Scanning guarantees that technicians are physically present. This easy-to-use solution motivates everyone to report incidents and help prevent disasters, in line with industrial best practices such as those of Lean Manufacturing (or TPM).

Reallocate time savings, close the ISO 55000 loop

bluebee® is the solution to the old chicken-and-egg dilemma of being too tied up with emergencies to spend time on improvement. Benchmarks show that technicians send up to 70% of their time on administrative tasks, looking for information, entering data, printing reports. bluebee® streamlines the entire process: time savings are immediately reallocated to prevention and high value-added work.

ISO 55000 calls for traceability in implementing the asset management strategy, with feedback form the field: bluebee® closes the feedback loop, filling the gaps left by traditional CMMS/EAM solutions.

Ensure regulatory compliance

Industrial risk prevention, in particular Health, Safety & Environment (HSE), is the top priority in today's increasingly regulated complex and challenging industrial environment. bluebee® was specifically designed to enforce best practices and regulations, by providing guidance from board room to technicians, and by monitoring work execution. Mandatory scanning for preventive maintenance, inspections, regulated work, helps ensure compliance. The system provides unprecedented traceability, making true data from the field immediately visible and auditable.